Bienvenidos a Langfang-bonai

Understanding the Production Process of ASA PVC Roof Tiles

Introduction: ASA PVC roof tiles are a popular roofing material choice due to their durability, weather resistance, and versatility in design. This article aims to provide a comprehensive overview of the production process of ASA PVC roof tiles, shedding light on the key steps involved in their manufacturing.

- Raw Material Selection: The production process begins with the meticulous selection of raw materials. The primary components include PVC resin and ASA (Acrylonitrile Styrene Acrylate) copolymer, known for their exceptional weather resistance and durability. These materials are stored in controlled environments to maintain their quality.

- Material Blending and Compounding: PVC resin and ASA copolymer are carefully blended in specific proportions to create a homogeneous mixture. This blending process is essential to ensure the final product's mechanical and chemical properties meet the required standards. Additives, such as stabilizers, fire retardants, and pigments, are also introduced during this stage to enhance the material's performance and appearance.

- Extrusion: The blended resin mixture is fed into an extruder, where it is heated and then forced through a die to form continuous sheets or profiles. This extrusion process imparts the desired thickness and shape to the ASA PVC resin material. Depending on the product specifications, extruded sheets of varying sizes and thicknesses are produced.

- Cooling and Cutting: Once extruded, the ASA PVC resin sheets are rapidly cooled to solidify the material. Cooling can be achieved through methods like air cooling or water cooling. After solidification, the sheets are precision-cut into the required dimensions using specialized cutting equipment, ensuring uniformity in tile size.

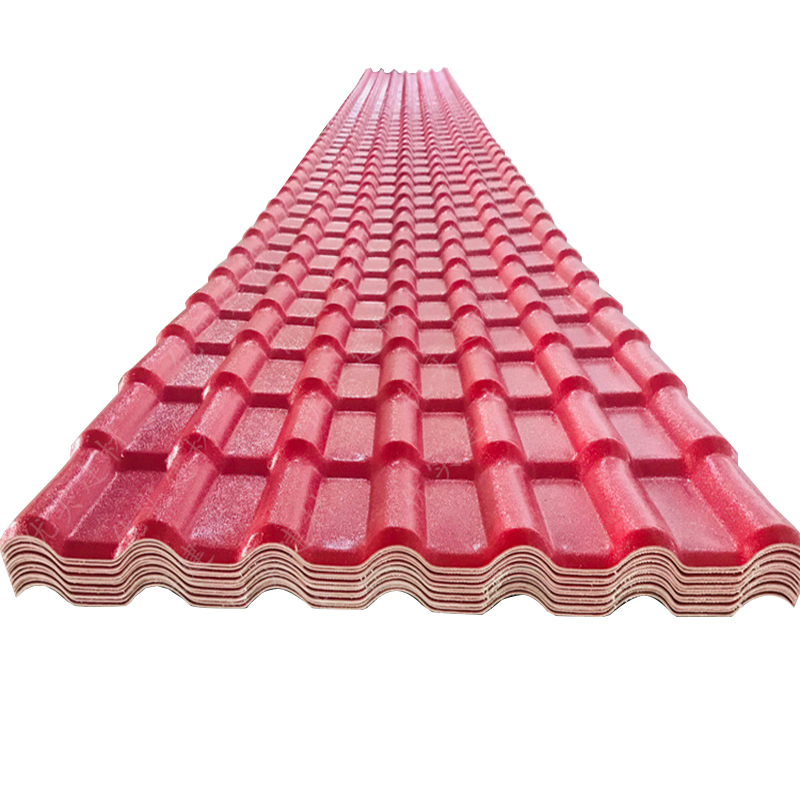

- Embossing and Surface Treatment: To enhance both the aesthetics and functionality of ASA PVC roof tiles, surface embossing may be applied. This step can create textures that replicate the appearance of natural roofing materials such as clay or slate. Additionally, a surface treatment is often added to improve UV resistance, colorfastness, and weather resistance, thus ensuring the tiles can withstand harsh outdoor conditions.

- Quality Control: Stringent quality control measures are implemented throughout the production process to monitor material consistency, tile dimensions, and overall product quality. This meticulous inspection ensures that each ASA PVC roof tile meets the required standards and specifications, guaranteeing durability and performance.

- Packaging and Distribution: Upon passing quality control checks, ASA PVC roof tiles are packaged for distribution. The packaging method depends on tile size and customer preferences. These high-quality tiles are then shipped to retailers, distributors, or construction sites, ready for installation on roofs around the world.