Bienvenidos a Langfang-bonai

Installation and Maintenance Guidelines for polycarbonate Hollow Panel | alveolar polycarbonate sheets

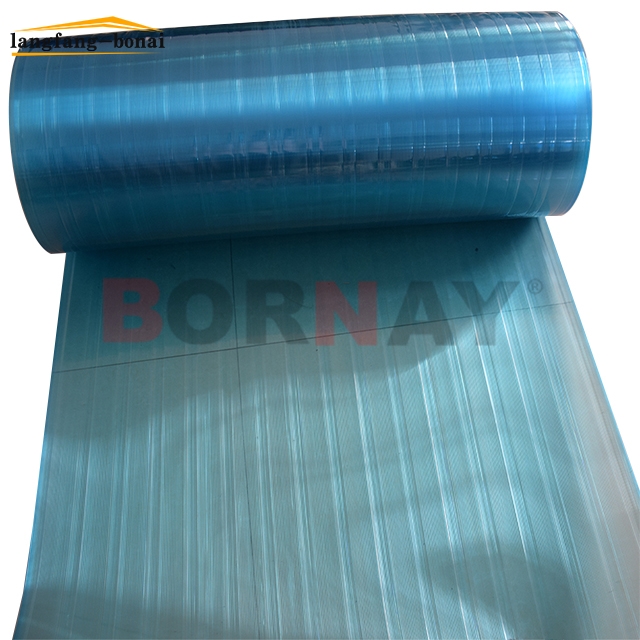

Polycarbonate Hollow Boards (PC hollow boards) have gained popularity in various construction and design applications due to their versatility, durability, and aesthetic appeal. To ensure the longevity and optimal performance of PC hollow boards, proper installation and regular maintenance are essential. This article provides guidelines for installing and maintaining PC hollow boards.

Installation Guidelines

- Prepare the Surface: Ensure that the surface where the PC hollow boards will be installed is clean, level, and free from debris. Any irregularities in the surface can affect the installation quality.

- Safety Measures: Prioritize safety during installation. Use appropriate safety equipment such as gloves, goggles, and helmets, especially when working with tools and machinery.

- Cutting and Shaping: If you need to cut or shape PC hollow boards, use a fine-toothed circular saw or a specialized cutting tool designed for polycarbonate materials. Ensure that the edges are smooth and free from burrs.

- Fastening: Secure the PC hollow boards using compatible fasteners, such as self-drilling screws with rubber gaskets to prevent water infiltration. Place fasteners at regular intervals along the edges and supports to ensure a secure attachment.

- Expansion Gaps: Allow for expansion and contraction of the PC hollow boards by leaving adequate gaps at the edges. Consult the manufacturer's guidelines for the recommended gap size, which may vary depending on the panel thickness and environmental conditions.

- Sealing: Apply a compatible sealant or weather-stripping material to seal gaps and joints, especially in areas prone to moisture infiltration. This helps maintain the weatherproofing integrity of the installation.

- Support Structure: Ensure that the support structure (e.g., framing or substructure) is robust and adequately designed to accommodate the weight and load-bearing requirements of the PC hollow boards.

Maintenance Guidelines

- Regular Cleaning: Clean the PC hollow boards regularly using a mild detergent and water solution. Avoid using abrasive cleaners or materials that may scratch the surface.

- Avoid Chemicals: Do not use harsh chemicals, solvents, or abrasive cleaning agents as they can damage the material. Test any cleaning product on a small, inconspicuous area first to ensure compatibility.

- Inspect for Damage: Periodically inspect the PC hollow boards for signs of damage, such as cracks, chips, or discoloration. Address any issues promptly to prevent further deterioration.

- UV Protection: If PC hollow boards are exposed to direct sunlight, consider applying a UV-resistant coating to protect against UV degradation. This step can extend the lifespan of the boards.

- Sealant Maintenance: Check the condition of sealants and weather-stripping materials. Replace any damaged or deteriorated sealants to maintain the weatherproofing of the installation.

- Snow and Ice Removal: In areas with heavy snowfall, remove snow and ice from the PC hollow boards using a soft-bristle broom or plastic shovel. Avoid using metal shovels or sharp tools that could scratch the surface.