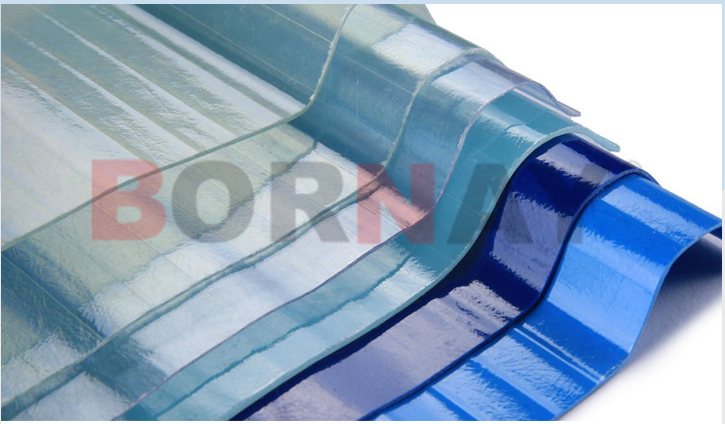

LANGFANG BONAI manufacture machine made FRP corrugated and Plain Sheet which is made from opaque and translucent fiberglass and UV protected resin. Our FRP Sheets are available in different thicknesses, sizes, and lengths. Our FRP Sheets are corrosion resistance, UV Resistance, Impact Resistance, and superior finish.

Manufacturing Process of FRP/GRP Roofing Sheet

LANGFANG BONAI manufacturing FRP Sheet through Fully Automated Intelligent Continuous Sheet Laminating Machine. It is a highly automated process which provides excellent quality & strength to FRP Sheeet.

Advantages of “LANGFANG BONAI ” make FRP/GRP Roofing Sheet

- Resistant to all types of weather

- Free from problems of cracking, wrapping and buckling

- High tensile strength

- UV Resistance

- Available in all colours

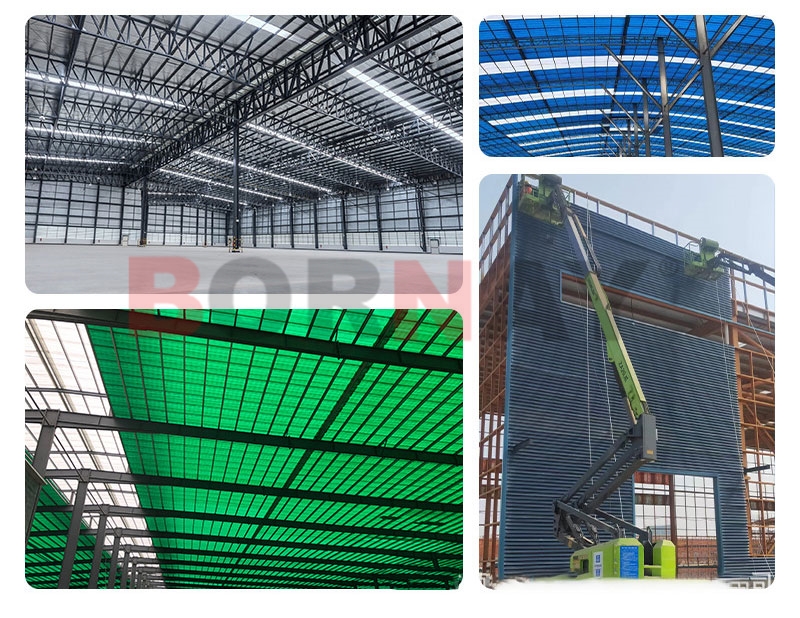

Applications of FRP Sheet

Industrial: Warehousing sheds, site cabins, security cabins, shelters, canteens

Domestic: Parking sheds, room extensions, toilets, bathrooms, roofing

Transportation: Bus station, ticket counters, parcel offices, shelters

Agriculture: Farmhouse, poultry farms, generator rooms, sheds

Technical Specification of Machine Made FRP GRP Roofing Sheet

Thickness: 0.8mm, 1.2mm, 1.5mm, 2mm, 2.5 mm, 3 mm, 4mm (±) 0.15 mm as per IS 12866 : 1989

Colours: Available in all colours

Profiles: Over 100 general profiles

Length: Cut as per customers requirement (provided it is suitable for transportation)

Density: g/cm 2 1.4 to 1.5M

Fiberglass content: >25%

Light transmission: 60-85%

Applicable temperature: 40°C to 120°C

Flexural Strength: Minimum value 500 kg/cm2 as per ASTM D 790 -92

Tensile Strength: Minimum value 500 kg/cm2 as per ASTM D 638-91

Compressive Strength: Minimum value 800 kg/cm2 as per ASTM D 695-91

Barcol Hardness: Minimum 40

Die Electric Strength: 14 kv/mm as per ASTM D 149-97a

UV Transmission: 0.30%

Wind Force: 220 N/mm2

WHY FRP SHEETS OVER GI SHEET

| FRP CORRUGATED SHEET |

GI CORRUGATED SHEET |

| Corrosion-resistant & so it requires less maintenance. |

Easily corroded & maintenance by doing re-painting. |

| High strength & stronger than GI sheets. FRP corrugated sheets do not deform under impact loads. |

Less strength & easily deform under high impact loads. |

| Light in weight and it weighs only 25% as compared to GI. |

Heavier as compared to FRP sheets and requires another lifting equipment to lift the GI sheet. |

| Less thermally conducted and does not expand or contract like metals. FRP sheets are safer to use as compared to metals. |

Thermally conducted and it undergoes expansion and contraction. |

| Longer life and are maintenance-free. pigments are added into the resin so it does not require repainting. |

Less life and requires repainting which adds to the cost of GI sheets. |

| used majorly in chemical industries, marine applications, industrial sheds. |

Difficult to use in chemical industries, marine applications where there is frequent corrosion which affects the life of GI sheets. |

We offer a wide range of machine-made FRP products, which are manufactured using superior grade raw materials like plastic, fiberglass cloth, fiber glass sheet, fiber glass sheet panel, metal roofing panel, fiberglass mat, fiberglass yearn, resin to ensure durable performance at client’s end.